Production in Aeronautical Institute

Aeronautical Institute’s production resource is greatly directed towards producing spare parts and assemblies necessary in the process of overhauling resources for which the Institute is qualified.

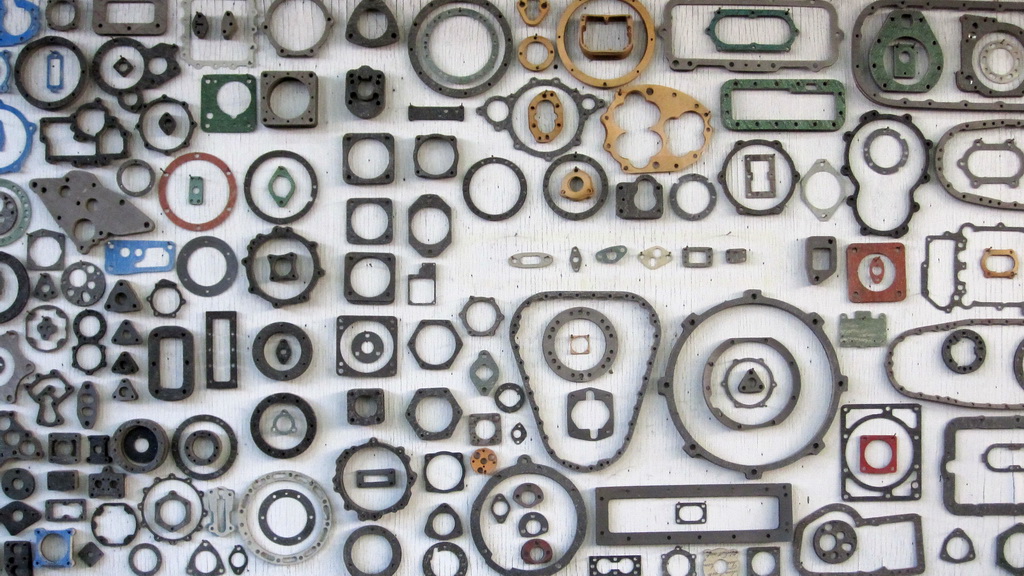

Aeronautical Institute ‘Moma Stanojlovic’ has achieved great results in the field of producing rubber parts. So far, it has mastered over 40 thousand of rubber parts or rubber-metal parts (various types of O-ring and plate gaskets, lip seals, suspensions, rubber pipes and other parts that are produced from rubber by spraying and pressuring based on silicone, fluorocarbon, polychloroprene, butanenitrile natural and other types of caoutchouc).

Institute has shown extraordinary results in applying composite materials in the production process. The last of such products, conducted according to the project of the Military Technical Institute, is a mini unmanned aerial vehicle ‘Vrabac”.

Following modern trends in the development of aircraft industry and increasing application of composites, technology for producing composite carrier rotor blades for helicopter Mi-8 has been mastered.

In accordance with that, the Institute provides services in producing composite parts according to the submitted drawing, using the procedure of molding, lamination, spraying, centrifugation, dunking and pressuring.

Within the production line of the Institute, we select the production of thermal insulation coverings made from fire-resistant stainless steel with filling made from wool insulation, as well as casings of exhaust engine arms for tanks Т72/М84.

Production capacities and technological possibilities enable for producing thermal insulation coverings for engines ‘viper’ (22-6, 531, 632-41 and 633-41) with exhaust gas temperature of 750 К, i.e. for engines with open chamber of additional combustion, temperature up to 1650 К.